Details of Drip Irrigation System:

Drip irrigation is an advanced method by using which there is substantial saving of irrigation water. This method can be adopted for most crops according to the type of soil the slope of the field, the source of water and the efficiency of the farmer. The irrigation efficiency of this method is about 80 to 90 %.

Along with increasing the yield of crops with this method high quality of produce, better use of chemicals and fertilizers, stop to misuse of water and reduction in flow, reduction in growth of weeds and huge water savings saving can be ensured.

Fast growing vegetables tips & tricks.

Use of this method of irrigation is increasing rapidly all over the world with limited water resources and increasing day by day, drip irrigation technology will proved to be very effective to reduce the need of water and environmental problems.

Drip irrigation technology is most suitable for successfully growing commercial crops in areas where land leveling is very costly and difficult and may even be impossible.

Drip irrigation is a high frequency irrigation system in which water is given around the root area of the plants.Drip irrigation can save fertilizer by 30 to 40%, save water up to 70%, increase yield by 100%, reduce weeds, save energy consumption and increase product quality.

Some of the main advantages of drip irrigation are

Water saving – This system can save water up to 70% and can be saved by filling the irrigation water level and does not go below the original area in the ground.

Proper utilization of water – Water use efficiency 80 to 90% and is used by drip irrigation method. In this method water wastage can be almost completely stopped.

Amla farming project for beginners.

Labor Savings – When there is very little labor required to start and stop irrigation almost daily, you can run it with very high cost savings.

Saline water – The use of saline water to irrigate often results in more moisture in the root zone of the plant, and the concentration of ions remains below harmful levels so that we can use saline water also in drip irrigation method.

Diseases and insects – The moisture concentration in the atmosphere around the plants remains low so the plants are less likely to get diseases and insects.

Use in poor soils – The distribution of water in the soil by drip irrigation can be planned according to the type of soil so drip irrigation can be used for irrigation for all types of soil.

Control of water – In drip irrigation it is possible to control the flow of water accurately and properly.

Technology that changes efficiency in agriculture.

Proper use of fertilizer – By the proper use of fertigation fertilizers does not get destroyed or leached due to efficient drip for this its efficiency in use increases. Multi protection Soil SP is partially controlled and moistened as soon as it is not felt in the soil.

Increase in yield – Drip irrigation helps to reduce water stress in the soil due to frequent irrigation and increases plant growth which increases the yield by almost 100%.

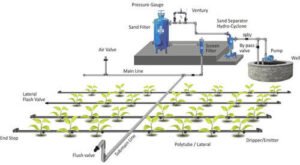

Drip irrigation is a network of pipes with an exhaust device. Drip irrigation systems consist of a main pipe, submain line and lateral pipes. Laterals are small plastic pipes that are attached to the hose with lateral pipes for uniform water distribution up to a level. The sub main pipe is designed to act as a control system and adjust the water pressure so that the required flow of water in each lateral. It also controls the irrigation time at different locations.

Drip system acts as a transport system for the total amount of water supplied to the main pipe. The irrigation system consists of auxiliary components to perform various functions such as a dripper head control unit, a filter and a ventury and many more.

In order to maintain the concentration of soil moisture required for plant growth pressure of the sytem is reached quickly as well as at a low rate of discharge. In drip irrigation, water is delivered drop by drop directly to the roots of plants. Drip irrigation system is irrigating with water you should keep the interval between irrigation so that the necessary moisture is available in the intoxication and the plants do not feel the stress of water.

Generally the irrigation interval do not kept more than 1 to 3 days. Due to which there should be no stress in the plants. By drip irrigation it is possible that the water requirement of the plant can be met in a timely manner.

How to do organic farming of capsicum?

Benefits of Fertigation:

Along with Drip Irrigation Fertigation is made up of two words Fertilizer and Irrigation. In drip irrigation, along with water, fertilizers are also delivered to the plants. In the same way, chemical fertilizer can be mixed with irrigation water and with the help of fertilizer & ventury, it can be delivered directly to the plants by drp & drop. Fertigation is the best and state-of-the-art method of giving fertilizer.

Fertigation in Drip is known to be a good technique to maintain proper level of fertilizer and water according to the requirements of the crop and soil.

Proper coordination of nutrients is the key to higher yield and quality. And can be combined with pre-planned irrigation at short intervals so that the plants get nutrients as per the requirement and valuable manure is not wasted by leaching.

Generally, only liquid fertilizer is used in fertigation but granular and dry fertilizers can also be given through fertigation. Before giving them by fertigation they are made into water soluble the to dissolve in the water.

At the the time of making soluble fertilizer also depends on the water temperature. One thing also we should keep in mind that before this to injecting in ventury first filter the solution and do the further.

Subsidy PMKSY per drop more crop schemes.

Economic Analysis of Drip Irrigation

There are two main things for successful adoption of drip irrigation technology was experimental and economic ease. Its high initial cost is the main problem in its installation. So with different crops of drip irrigation system financial capability cost benefit ratio analysis of cost and cost is necessary.

Cost of installation of drip irrigation system depends upon type of main crop Distance between rows to row and plant to plant and Irrigation interval. The water requirement in crops depends on the type and capacity of the dripper and the distance of the water source. About 50% of the total cost per unit of drip irrigation is spent on the lateral pipe only. As the area of drip irrigation increases, the proportionate cost of drip irrigation system decreases as compared to that because some of the components of the irrigation system are the same.

In nearby crops, the cost of installing permanent drip irrigation is often higher than that of sprinkler systems because the lateral pipes are closer. The energy requirement and labor cost are also less in the normal system. The cost of applying drip in interval horticulture crops is less than our system because lotus diameter pipe can be used due to less removal from the top. The following are the main components of a Drip System:

Filteration Unit:

Filters are used for different types of impurities such as Fungi, soil particles, sand, chemical and fertilizer residues used in cleaning and removing etc. In order to prevent the emitters from being turned off.

How to use GIS in agriculture?

Filters are installed at the beginning of the irrigation system. On the basis of the quality of water and the source of water, different types of Filters are used.

Primary Filters:

- Sand filter

- Hydro cyclone filter

Secondary filter

- Screen filter

- Disc filter

Sand filter

It is a metal cylinder tank with sand as the filter medium. It is 2 mm to 4 mm diameter shaped silica is sand. This filter is mainly used in open wells, borewells, tube wells, ponds, rivers and canals etc.

These filters are effective against organic and inorganic suspended solids. Dirt and mold are trapped and the filter unit is collected inside the sand medium. There are two types of sand filters on the basis of size, such as single layer filter and multi layer filter. Single layer filters have the same size of sand and multi layer filters have different sizes of sand. On the basis of shape, there are two types of sand filters, horizontal and vertical sand filters. You can go as per your choice.

Generally multi layer sand filter is used for cultivation in green house. The capacity of sandfilter is always given in meter cubic per hour. The filter capacity is selected according to the need of the water. Various capacity sand filters are available in the market, which range from 15, 25, 40 to 50 cubic meters per hour.

How can you use industrial water in agriculture?

Hydrocyclone filter

This filter is known as centrifugal filter or sand separator. On the basis of vertical motion and centripetal force, these filters remove suspended matter.

Such filters are effective only when solid particles are of higher density than water. These filters are installed near the well. They separate a large amount of sand and pebbles from the lifted water. These raised sand and pebbles get deposited in the special tank of hydrocyclone. Hydrocyclone pellets of 40 and 50 cubic meter per hour capacity are available.

Screen filter

This filter consists of a screen which is mounted in a cylindrical form and it is made of metal or plastic material. is made of.

The size of the pores on the screen is measured in terms of mm, micron or mesh. It refers to the holes found in a square inch area. Generally 100-200 mesh is selected for drip irrigation. Screen Filter Foot: Applied to the stream below the sand filter and can be applied with or without a sand filter depending on the type of water.

When water passes through the filter a certain amount of dirt accumulates on the top of the filter, increasing the pressure of the droplets. In this stage cleaning of the screen becomes necessary. Screen cleaning is done by hand or by machine washing. There are screen filters available in the market with different capacities of 10, 15 and 25 cubic meters per hour.

Agriculture schemes run by Indian government.

Disc Filter:

The filter is made of a plastic disc, which is wrapped around a telescopic core. Water passes through the filter from outside to inside. The filter is affected by two conditions. The large outer area which filters the larger particles and the inner grooves which are made inside the disc block the fine particles. The filter can be easily opened and cleaned.

The disc can be disassembled and cleaned thoroughly with water. There are disc filters available in the market with different capacities ranging from 15, 25, 40, 50 and 60 cubic meters per hour to cleaning.

Non Return Valve:

When the pump is turned off the water located in the pipe puts pressure on the pump as soon as it is turned off which can cause damage to the pump, this valve does the job of protecting it from damage.

Air Release Valve:

This valve is mounted at the top of the mechanism, caused by air at the beginning of the system.

Control Valve:

Basically it is use to control the fow of water inside the p;pe line of Drip System. It is designed as per the capacity of the system. You can select that on the basis of pipe line diameter.

Flush valve

These valves are used to flush the sub main drain at its last are attached at the ends. Filth accumulated by them 7 Soil particles are cleaned.

Bypass valve

The filter is installed before the unit thereby Water supply can be regulated and pressure also can be done regularly.

How to do green house farming?

Main Line and Sub Main Line

Main line and sub main line water filter and sends it from the system to the emitters. it is usually frommade up of PVC and HDPE which is made of Protects from corrosion effect and clogging.

Lateral

Lateral are flexible pipes/ducts of fewer diameters, made of low-density polyethylene. It is 12 mm in diameter, 16 mm and 20mm.They are black in color so that inside them the fungus does not grow and is exposed to ultraviolet rays. It prevents side effects. This is done per square cm. can bear the pressure. From the sub main line is added.

Drippers:

Drippers are also known as emitters, which that the water is drawn from the lateral to the root zone of the plant. Put drippers on or inside the lateral. Here there are two types of laterals their position according to.

- online drippers

- inline drippers

Online drippers

In this method, drippers are placed on the laterals depending on the type of soil and crop transfer. It is mainly used in surface Drip system. They are mainly used in high transfer horticulture crops and seasonal crops. In this the discharge rate of water, 4, 8 and 14 liters per hour.

How to do protective cultivation?

Inline Driplines

In this method the drippers are kept inside the laterals at the time of construction of the factory. The location of the seeds of the two drippers depends on the type of soil and the transfer of the crop. It is mainly used in crops and vegetables grown in dense rows.

- Non Pressure Compensating Drippers (NPC)

In open farming mainly NPC Drippers are used. In this type of drippers, the discharge increases as the pressure of the working system increases. This type of emitters is suitable for flat land.

- Pressure Compensating Drippers (PC)

The PC drippers are made in such a way that this is the pressure, the donated water continues to be discharged at a regular rate at a wide working pressure. Most pressure adjustments do not work. Drippers are activated only at low pressures. This type of drippers is especially suitable for high-low areas .

Pressure gauge

Pressure plays an important role in drip irrigation system. Pressure is measured with a pressure gauge. High pressure pipe May damage lines and drip system at low pressure doesn’t work. It ranges from 1.0 kg to 2.0 kg. per cm square the meter operates on pressure.

Pressure gauge position

It is located at the inner and outer flow ends of the filter are put. If the pressure gauge is the same at both ends shows pressure. it means that the filter is working properly and if the pressure gauge If both the places are telling different pressure then its means that the filter has accumulated dirt, or sand or mold Has been. So it needs to be cleaned up.

a) Pressure gauge on the main line

A pressure gauge is placed at the starting point of the main line, so that the pressure of the main line can be seen whether it is correct or not.

Best farming method to grow garlic in India.

b) Measurement of pressure in the lateral

This pressure gauge is applied at the ends of the initial lateral line and at the ends of the final lateral line to test or observe the pressure transfer in the lateral line. If the pressure gauge shows high pressure, it means that the lateral line needs to be cleaned.